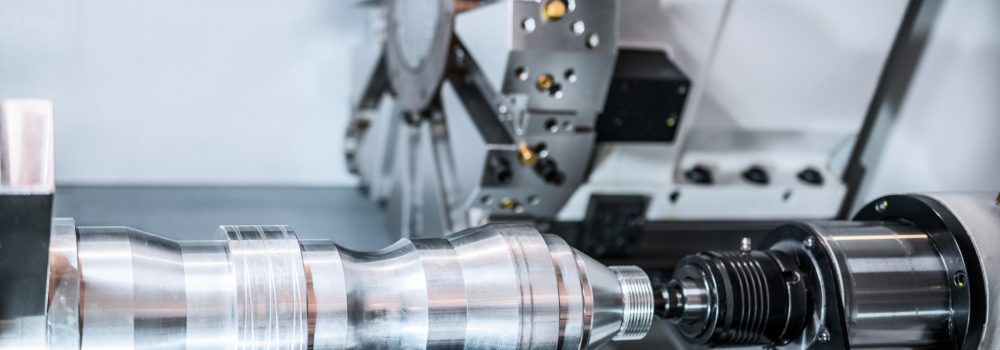

Non-Metalic Lathe Cutting

At Edgewater, we offer superior options in lathe cutting. Our precise, custom manufacturing services allow us to form various non-metallic materials into precise, desired shapes.

In fact, our lathe cut gaskets offer smoother and better seals, and we’re proud to offer lathe cut materials that can then be cured over a mandrel to ensure that the inside diameter meets specifications and ground to ensure the outside diameter also meets our stringent quality controlled specifications. These cured tubs can then be cut to proper widths on lathes (bayonets) that provide precision cut width.

With our automatic lathe, the workpiece is held and rotated while a tool bit performs the cutting action. We are able to use drills and bayonets to create tapers, drilled holes, chamfers, and other complex shapes. Our lathe cutting system allows us to do simple 2-axis cuttoffs and more complex, multi-step operations.

Advantages of Lathe Cutting

The lathe cutting process offers many advantages, especially when compared to injection molding and die cutting. For example, our capabilities include both single and double bevel cut gaskets, which are used in high performance sealing applications.

Lathe cut gaskets, for example, offer distinct advantages over O-rings, gaskets, and washers manufactured using other methods such as injection molding and die cutting. They can be made out of any polymer group and offer distinct cost savings for custom sizes, since there is little to no tooling required in the lathe cut process.

Other advantages of Lathe Cutting include:

- No mold flash, pits, voids, or non-fills

- Maximum sealing surface, compared to standard o-rings

- No hourglassing vs. die-cut products

- Lower product cost, low or high volume

- Smooth surface finish without parting line or flash

- Guaranteed parallel cut surfaces

Best Choice for Lathe Cutting

With Edgewater, you’ll also have quick turnaround time, as the limited tooling of the process allows us to move quickly. We can work with you to create the custom shapes you need, and we can work with you to meet your timeline and budget.

At Edgewater, quality and craftsmanship are part of our process. Our experts can recommend the best tools and materials for any manufacturing application. To learn more about our lathe cutting process and other services we offer, contact us today to get started.